Automotive Industries

Automotive Industries

Automotive Industries

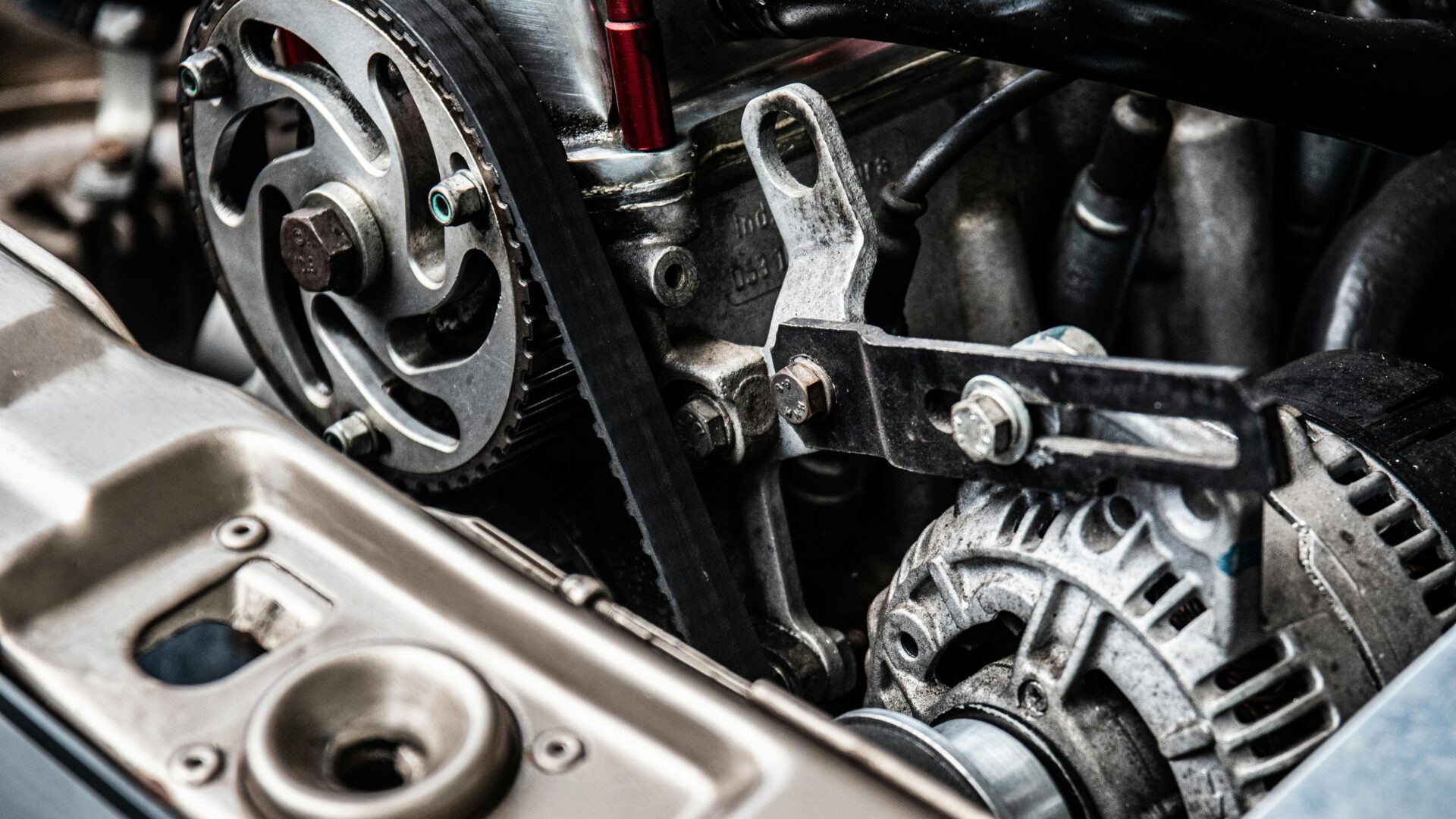

The automotive industry moves fast – really fast. With high-volume production and demanding precision, there’s no room for inefficiencies. Whether it’s engine components, suspension parts, or structural elements, CNC machining plays a critical role in keeping manufacturing streamlined and cost-effective.

But when vibration interferes with the process, things slow down. Tool wear increases, surface finishes suffer, and production costs creep up.

That’s where MAQ’s vibration-damped machine tools and self-tuning mass dampers come in. By eliminating the need to reduce cutting speeds or limit the depth of cut, they help manufacturers keep cycle times low and tool life high – without breaking the bank on expensive vibration-damping alternatives.

Discover our full range of tools for high-speed, high-precision machining.

Vehicle manufacturers don’t have the luxury of slowing down. Whether producing 100,000 engine blocks or fine-tuning custom suspension parts, efficiency is everything. But here’s the problem – when cutting forces cause chatter and instability, manufacturers often compensate by reducing speeds or taking shallower cuts. That might solve the immediate issue, but it drags out cycle times and increases tooling costs over time.

MAQ’s STMD™ technology changes the equation. These tool holders automatically dampen vibration in real time, allowing manufacturers to push cutting speeds without sacrificing quality. The result? Faster machining, better surface finishes, and extended tool life – all without constant adjustments or expensive alternative solutions.

Need help finding the right tool for your machining setup?

Precision machining isn’t just about getting the job done; it’s about getting it right every single time. Inconsistent surface finishes, premature tool wear, and unpredictable performance create bottlenecks in automotive production lines.

STMD™ tool holders eliminate these inconsistencies by reducing vibration at the source. That means:

For manufacturers, this means fewer rejected parts, reduced downtime, and a machining process they can rely on day in and day out.

CNC machining in the automotive industry isn’t just about precision – it’s about profitability. Every second saved on cycle time, every tool that lasts longer, and every part that meets spec without rework contributes to the bottom line.

MAQ’s vibration-damping solutions aren’t just about keeping machines running; they’re about keeping businesses competitive. With the ability to push speeds and feeds without the usual drawbacks, manufacturers gain an edge in both performance and cost-efficiency.

Looking for a machining solution that keeps up with your production demands? MAQ’s STMD™ tool holders are used worldwide by manufacturers that prioritize efficiency and reliability.

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.