At the core of MAQ’s innovation lies a groundbreaking method for vibration dampening. While competitors traditionally relied on rubber rings to support mass in their dampening systems, MAQ took a different path by integrating nanostructured polymers. This fundamental shift in material composition offers a significant advantage. Nanostructured polymers, with a structure size below 20 nanometers, outshine rubber, which typically exceeds 200 nanometers. This finer structure enables enhanced frequency stiffness properties, resulting in superior vibration dampening capabilities across a broader frequency band. This unique approach is what sets MAQ apart, not just today, but throughout history.

The Evolution of Damped Bars: A Historical Perspective

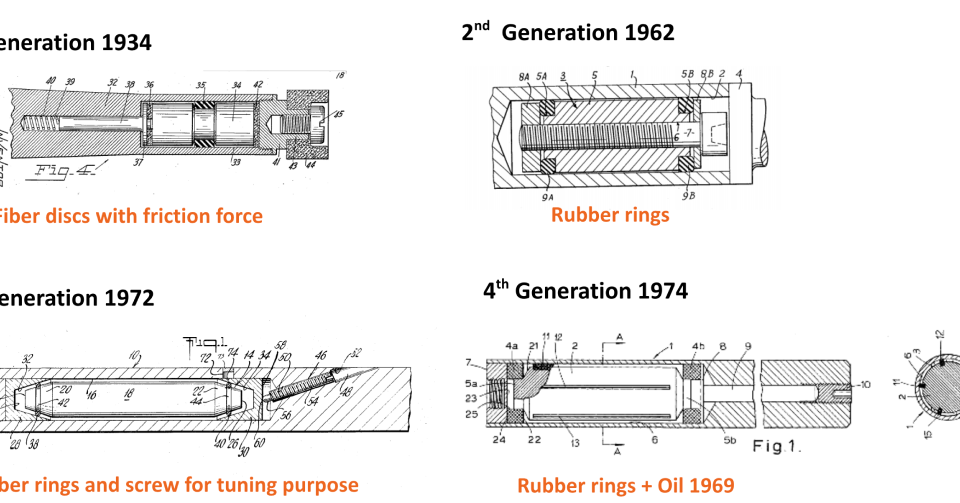

The concept of damped bars has a storied past, dating back to 1934 when the first US patent introduced fiber disks originally designed for automotive clutches. These disks were strategically positioned to support the mass, with an external screw applying pressure to fine-tune the frequency.

In 1962, engineers introduced a second concept, incorporating rubber, a widely available commercial product. Compressed rubber rings, manipulated by a screw, became the go-to method for finding the optimal frequency.

The evolutionary journey continued in 1972 with the introduction of the tunable-bar system in the US. This system utilized an external screw to exert pressure on a rubber gasket, indirectly influencing the mass damper to determine the correct frequency.

Norway entered the innovation landscape in 1974 with the viscous-oil solution. By acquiring the inventing company, they employed two rubber rings surrounding the mass, immersed in oil. While the patent was updated in the 1980s, it remained true to the original design.

The Dry Distinction

MAQ enters the scene with the 5th generation mass damper – a revolutionary nano approach. Our system introduces a polymer with frequency dependent stiffness, offering a dry alternative. This innovative polymer dynamically adjusts stiffness based on frequency in mere nanoseconds, marking a paradigm shift in the industry.

Unlike competitors who often resort to incorporating dampening oils for enhanced performance, MAQ’s solution remains purely dry. This not only simplifies maintenance but also eliminates the risk of oil leakage, ensuring consistent and reliable performance over time.

The Evolution of Tailored Solutions

MAQ’s innovation journey stems from extensive research and development efforts across multiple disciplines, including metal cutting research, structural vibrations, and material science. By comprehensively understanding these domains, MAQ pinpointed the inherent challenges in machining vibrations and devised a solution tailored to address them effectively.

Comparing MAQ’s approach to its competitors, it’s evident that while others focus on incremental improvements or software-based solutions, MAQ takes a bold step forward with its material-centric innovation. This shift in focus enables MAQ to not only solve existing challenges but also anticipate and proactively address emerging ones.

Looking Ahead

In ongoing research and development endeavors, MAQ remains committed to refining our solution and exploring new avenues for improvement. From tackling challenges in rotating components and products, to exploring novel materials and manufacturing techniques, MAQ continues to push the boundaries of what’s achievable in vibration dampening technology.

Looking towards the future, MAQ envisions a world where machining is simplified, and productivity is maximized. By staying true to our mission of simplifying machining processes and enhancing productivity, we aim to still be leading innovation in the years to come.