Using Ceramic inserts and CBN inserts requires stable machining. Perfect for MAQ tools!

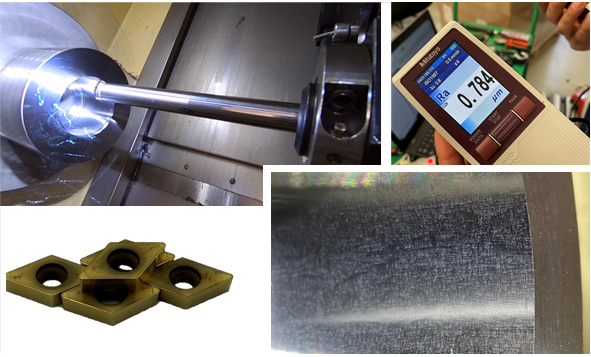

When machining HRSA (Heat-resistant Super Alloy) and case-hardened steel, Ceramic inserts, and CBN/PCBN inserts are often used to boost productivity. With the higher cutting speed, CBN inserts, and Ceramic inserts outperform cemented carbide with a higher material removal rate when machining HRSA and case-hardened steel.

The challenge of using CBN inserts, and Ceramic inserts is that they require a stable-machining process without vibrations. Due to the high hardness of these materials, they naturally have lower toughness compared to cemented carbide. A slight vibration in machines can lead to edge fracture immediately, and this put high demand on the tooling system’s rigidity and vibration damping.

Due to the high localized temperature, machining of HRSA and case hardened steel is challenging. CBN inserts and Ceramic inserts both have high hot hardness and present a higher cutting speed compare to the cemented carbide. The depth of cut and feed is, however, limited by the toughness of the insert base material and edge design. With the higher cutting speed, CBN inserts and Ceramic inserts outperform cemented carbide with a higher material removal rate when machining HRSA and case hardened steel. The challenge of using CBN inserts and Ceramic inserts is a stable machining process without vibrations. Due to the high hardness of these materials, they naturally have lower toughness compared to cemented carbide. A slight vibration in machining can lead to edge fracture immediately, and this put high demand on the tooling system’s rigidity and vibration dampening.

MAQ STMD damped turning tools are superior to all other solutions on the market when it comes to dampening vibrations and creating stable machining and are therefore the perfect choice when using Ceramic and CBN Inserts. This is proven by dozens of user cases on the market, using MAQ STMD damped turning tools in combination with CBN and Ceramic inserts when machining HRSA and case-hardened steel.

Should there be a challenge, give a call to the MAQ team for tech support!