We’re excited to announce the launch of our Monoblock Diamond Burnishing Tools, available in two sizes: 12 mm (1/2”) and 16 mm (5/8”).

Why Choose Diamond Burnishing?

Diamond burnishing provides exceptional surface finishes that rival grinding, all while utilizing a turning machine. Many of our customers have reported significant cost savings by adopting diamond burnishing to eliminate post-processing steps.

With diamond burnishing, you achieve not only a brilliant, mirror-like finish (Ra < 0.4 µm or 16 µinch) but also enhanced hardness, reduced friction, and increased corrosion resistance. This process notably elevates the functionality and durability of your machined components, making them better suited for end-use applications. Most metallic materials can benefit from burnishing, improving both their appearance and performance.

Want to know which industries are showing great interest in our tools?

Contact us for more information.

Expanding Our Portfolio

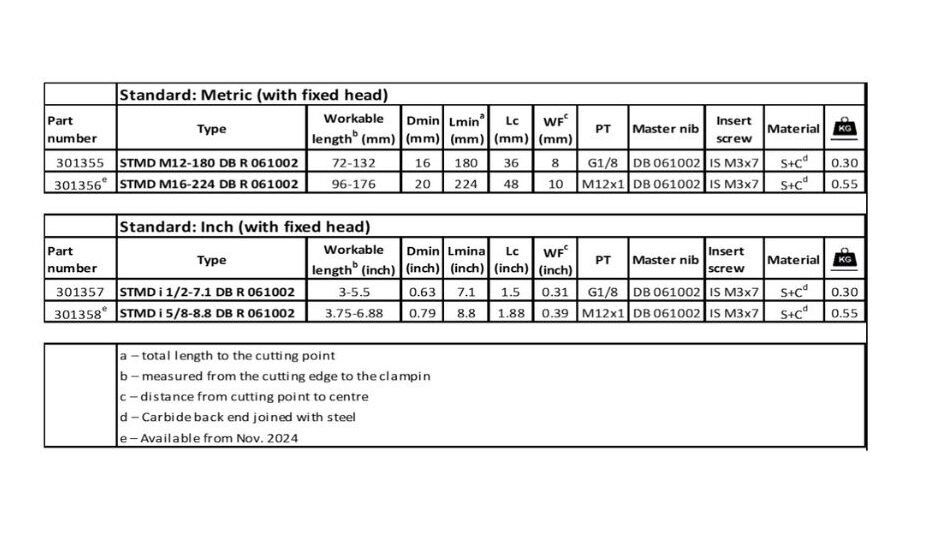

To maintain our leadership in the market, MAQ is excited to expand our diamond burnishing lineup with four new products. These tools cover diameters of 12 mm (1/2 inch) and 16 mm (5/8 inch) for hole sizes of 16 mm (5/8 inch) and 20 mm (3/4 inch), respectively.

Facing Challenges with Small Components?

If you’re dealing with smaller components and struggling with surface finish, look no further. MAQ offers the world’s smallest vibration-damping tools, designed to tackle those tough challenges.

Connect with our Mechanical Engineer to explore how these tools can support your precision and efficiency.