Curiosity has always been a character from MAQ, and we are always interested to know the physical limits of machining systems. Being told by the market to be very careful with internal grooving operation due to its vibration problem, we are today presenting our machining results of internal grooving at 10xD.

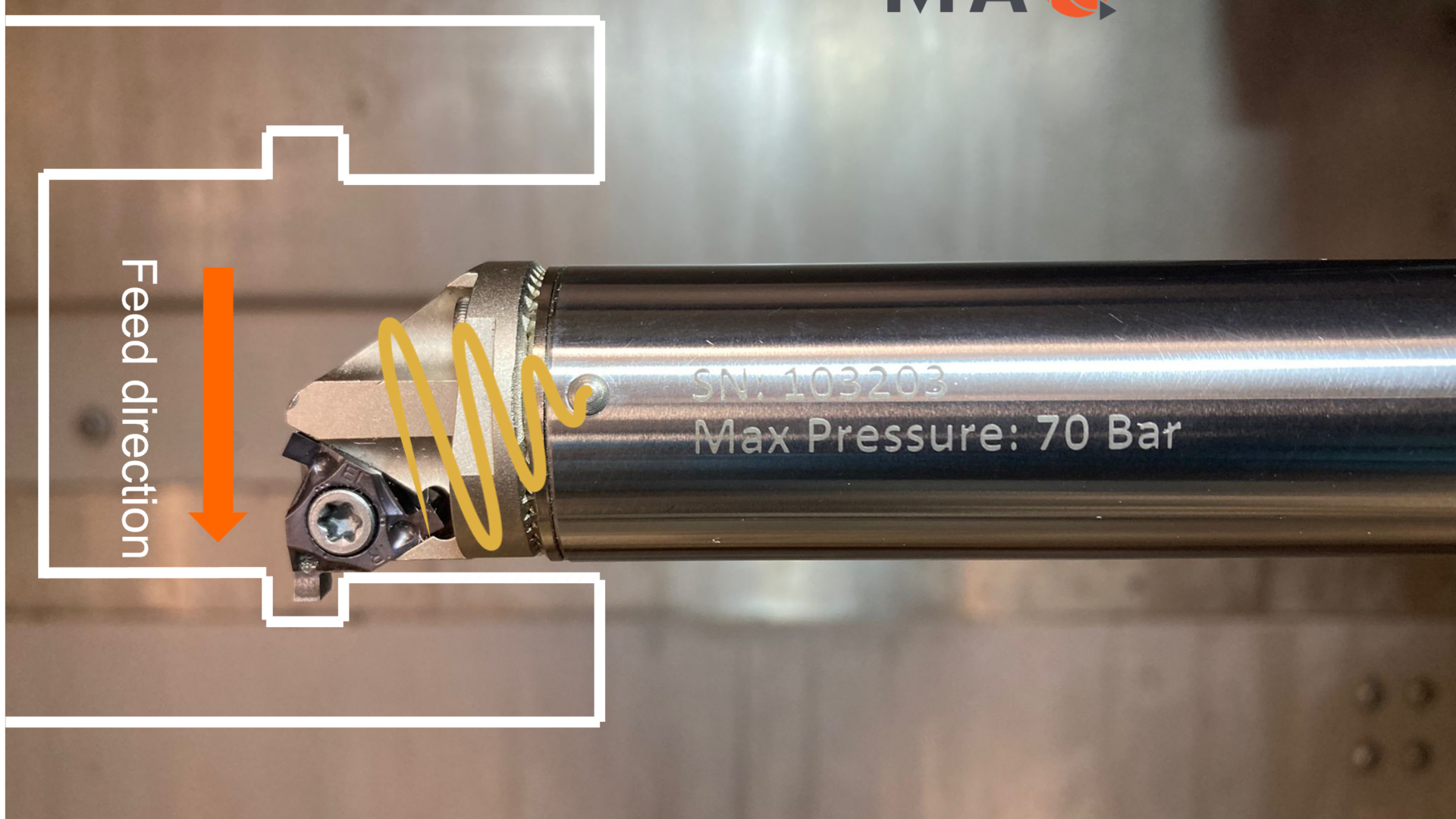

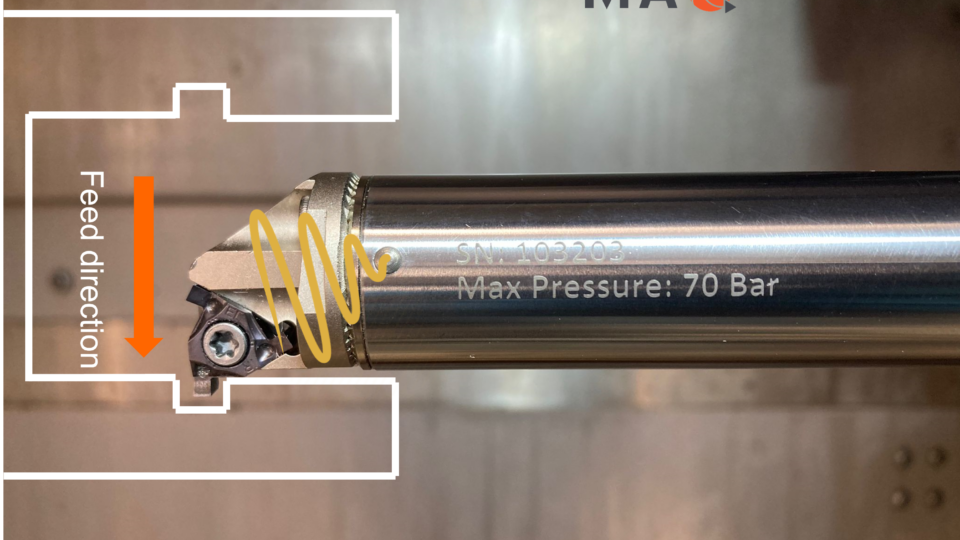

Using an STMD M32-416 product, which is a standard steel bar damped with the STMD technology, with an SXFNR 322028 16 cutter head and 16 IR W 2.25 insert, we perform grooving at 10xD overhang length. The machined workpiece material is 4340 34 CrNiMo HRC 30. Thanks to the STMD technology, with its Self-Tuning capabilities, the tool adapts to different types of vibrations, and the limits are again pushed by MAQ.

See the video here. https://youtu.be/_-SndCbNHPU

Need to make a shallow groove for an O-ring seat or retaining rings? The standard selection of 16mm trigonal grooving inserts can help you make grooves with a max depth of 2.25mm. The width can be widened by a longitudinal turning operation.