Speed is the key!

Ever since machining was invented, speed is the key to success. It is directly related to the productivity of a manufacturing system, and the faster the better. We often hear people say that you can use a carbide tool if you want to reach over a 5xD setup. Although you have to slow down to stop the tool from vibrating and destroying the surface. But even if you would have an infinite amount of time (which you of course don’t have), you cannot go slower than the speed at which you create a chip in machining, i.e. there is a limit to how slow you can go.

The question is, do you want to slow down? Everyone talks about going faster, Inventors and researchers have spent years of effort to develop a cutting insert that makes it possible to cut faster. The problem is when you need to go deeper than 5xD, the weakest link will be the Carbide bar and you just have to accept it. Scandalous! It’s time to wake up and start to explore a new solution that will increase your productivity dramatically and make use of those expensive, specially developed superfast Inserts.

MAQ STMD products in the 5xD series, outperform the carbide bar, in every corner, in the range between 4–7xD setups. With the MAQ tools, you can fully utilize the potential offered by the inserts and machine. Let’s look at the maximum speed performance comparing our STMD M25-205 SDUCR product to the carbide bar:

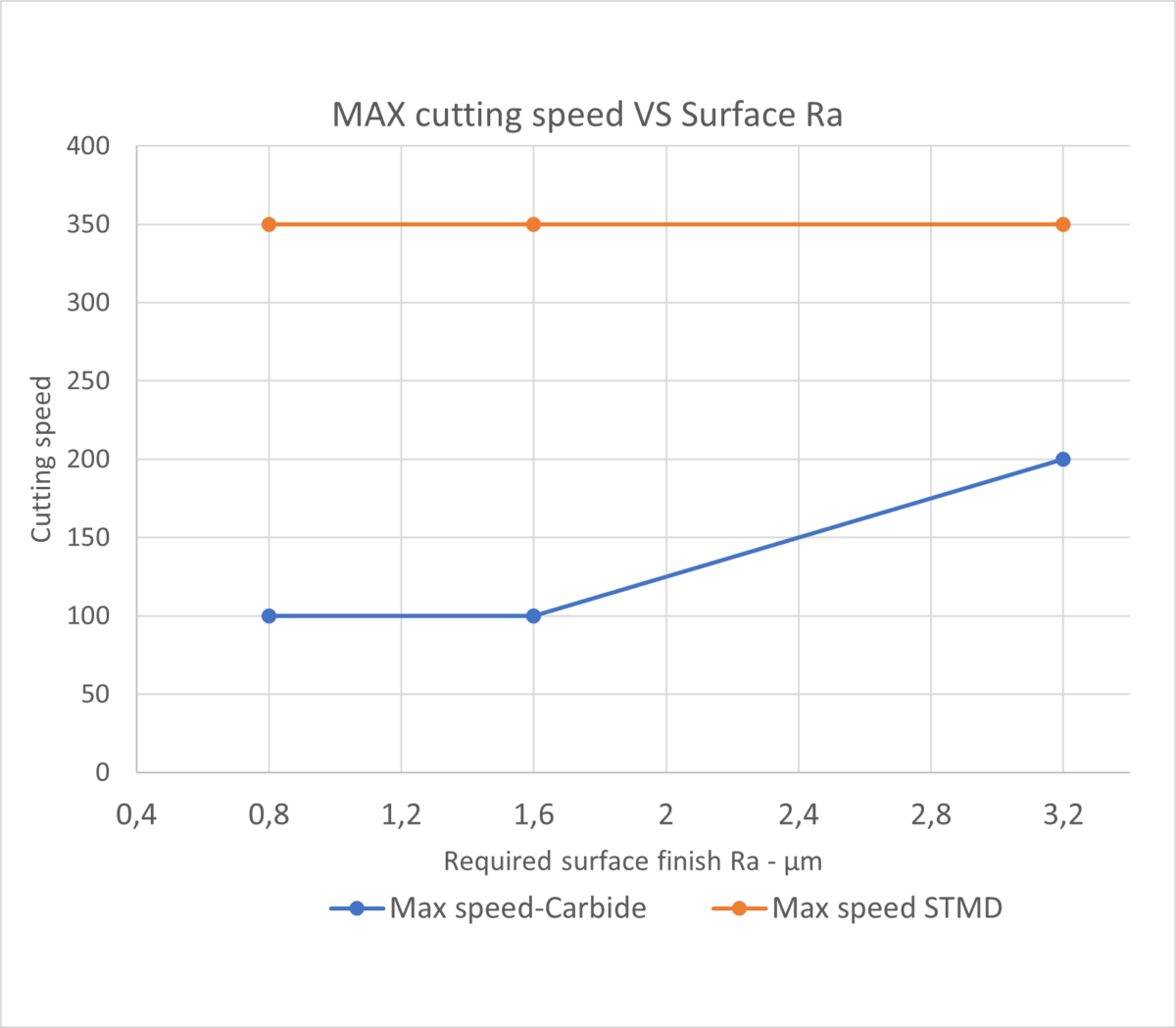

Figure 1, maximum allowed cutting speed Vs required surface finish, comparing STMD M25-205 SDUCR and equivalent carbide tool, at 6xD setup, depth of cut ap was fixed at 0.25 mm, the workpiece material is 34CrNiMo – 4340 steel HRC 28-30, coolant was used during the test and the cutting insert is MAQ DCMT 11T304 FP – P25C.

As you can see, if we have a surface finish requirement of Ra 1.6 µm, a carbide tool needs to reduce the cutting speed below 100 m/min, whereas the STMD M25-205 SDUCR product can do the same job at 350 m/min (maximum recommended for the insert), a 250% increase in cutting speed – a 71% reduction in cycle time. This means that you can produce 250% more components with the same machine, same inserts, same fixtures, same programs, and even the same coffee, just by switching from your Carbide tool to the MAQ STMD product.

So, what is the hatch? Are the STMD tools expensive? Nope, and now it gets really disruptive for the Carbide fans (and our competitors). The MAQ 5xD tools cost approximately the same as a carbide tool and you can produce 250% more parts with the same or better surface finish. Your other option is to buy two more machines to manage the volume. Give yourself a break and free over 70% in your machine by switching to MAQ 5xD!

It is your machine, and of course, it is your choice but let’s speed up and Simplify Machining together!

Our mission is to bring new technology to the workshops to make things better, faster, and easier. “Simplify Machine” in other words!