For more than a century, machinists have been battling the same enemy: vibration. Known as chatter when it spirals out of control, vibration ruins surface finishes, wears out tools, and forces operators into compromises that slow production.

Everyone knows vibration is a problem, but for some reason, the industry has largely accepted it as unavoidable.

That era is over.

The Old Story: Acceptance and Workarounds

Traditional vibration control often relied on tuned mass dampers. These devices could reduce chatter, but they had a major flaw: they needed to be manually tuned to match the specific vibration frequency of each setup. Change the tool length, material, or cutting conditions, and the damper was out of tune.

Instead of solving the root cause, they developed workarounds:

- Cutting speeds were lowered to keep chatter under control, sacrificing productivity.

- Extra passes and polishing were added to fix poor surface quality.

- Inserts were swapped more often, accepted as part of the cost of doing business.

These fixes kept parts within tolerance, but at a high price – slower cycle times, higher tooling costs, and increased operator stress.

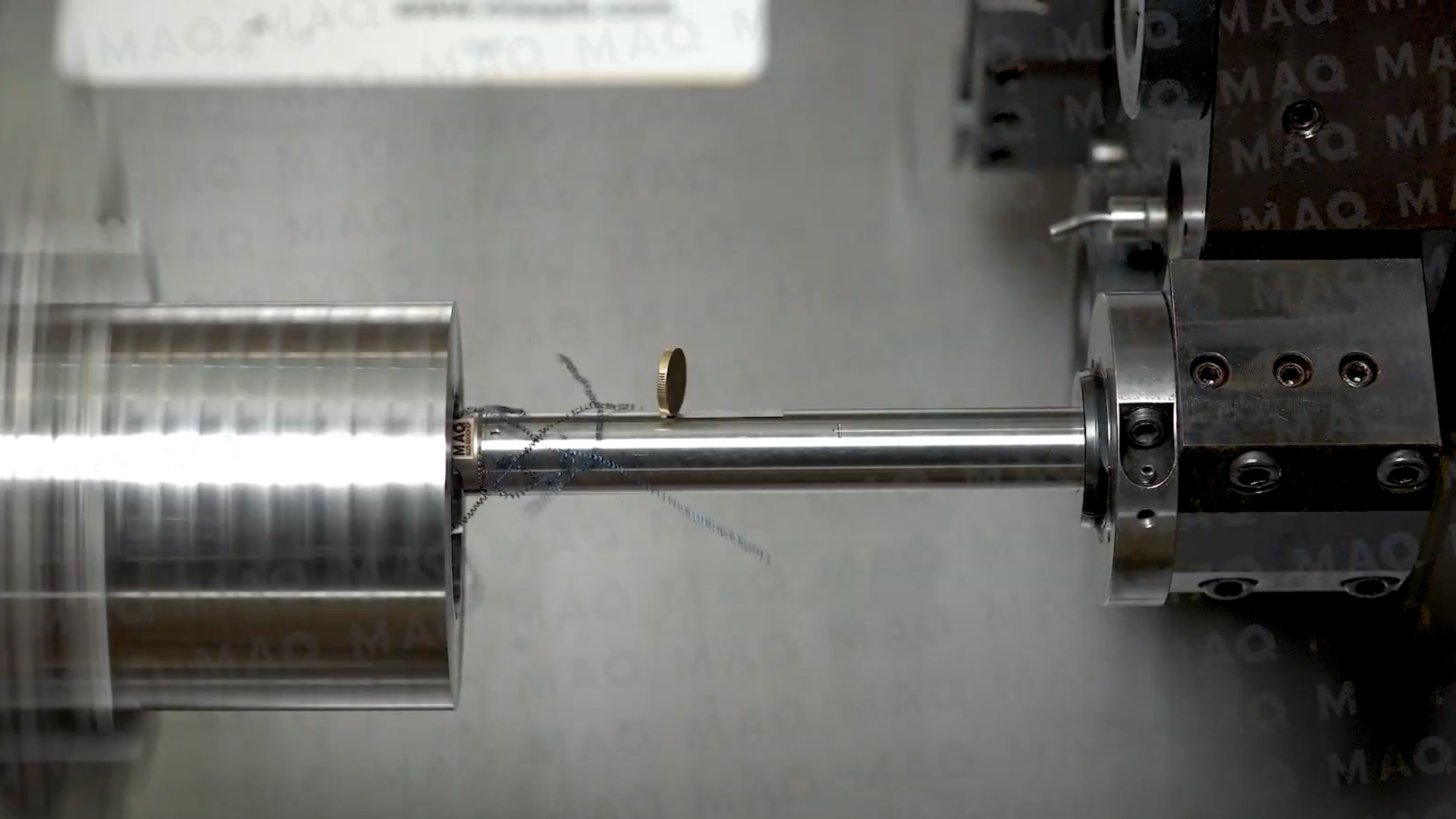

A New Answer: Plug-and-Play Vibration Control

MAQ’s technology breaks with that history. Unlike traditional dampers that require manual tuning, MAQ tools automatically adapt to vibration frequencies. There’s no additional setup or calibration – just stable, chatter-free cutting from the first pass.

In practice, that means:

- Plug-and-play simplicity – install the tool, start cutting, and the damping effect engages instantly.

- Higher cutting speeds without chatter, eliminating the need to sacrifice productivity for stability.

- Consistent surface finish that reduces or removes the need for secondary operations.

- Extended tool life, as vibration no longer accelerates wear.

For machinists, that translates into fewer compromises and more confidence that the process will deliver – part after part.

Cutting Without Compromise

Manufacturing today doesn’t have room for inefficiency. Aerospace parts worth thousands can’t be scrapped. Automotive production can’t slow down for extra polishing. Medical components can’t risk inconsistency.

So why should machinists – or the industry as a whole – keep living with vibration?

For generations, machinists endured chatter because there wasn’t a better alternative. Today, there is. MAQ’s technology eliminates vibration as a limiting factor – without extra setup, tuning, or guesswork.

The age of tolerating vibration is over. It’s time to eliminate it.

Want to know more? Contact us today and experience the future of machining, now.