Contact-CTA or newsletter signup

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

Whitepaper

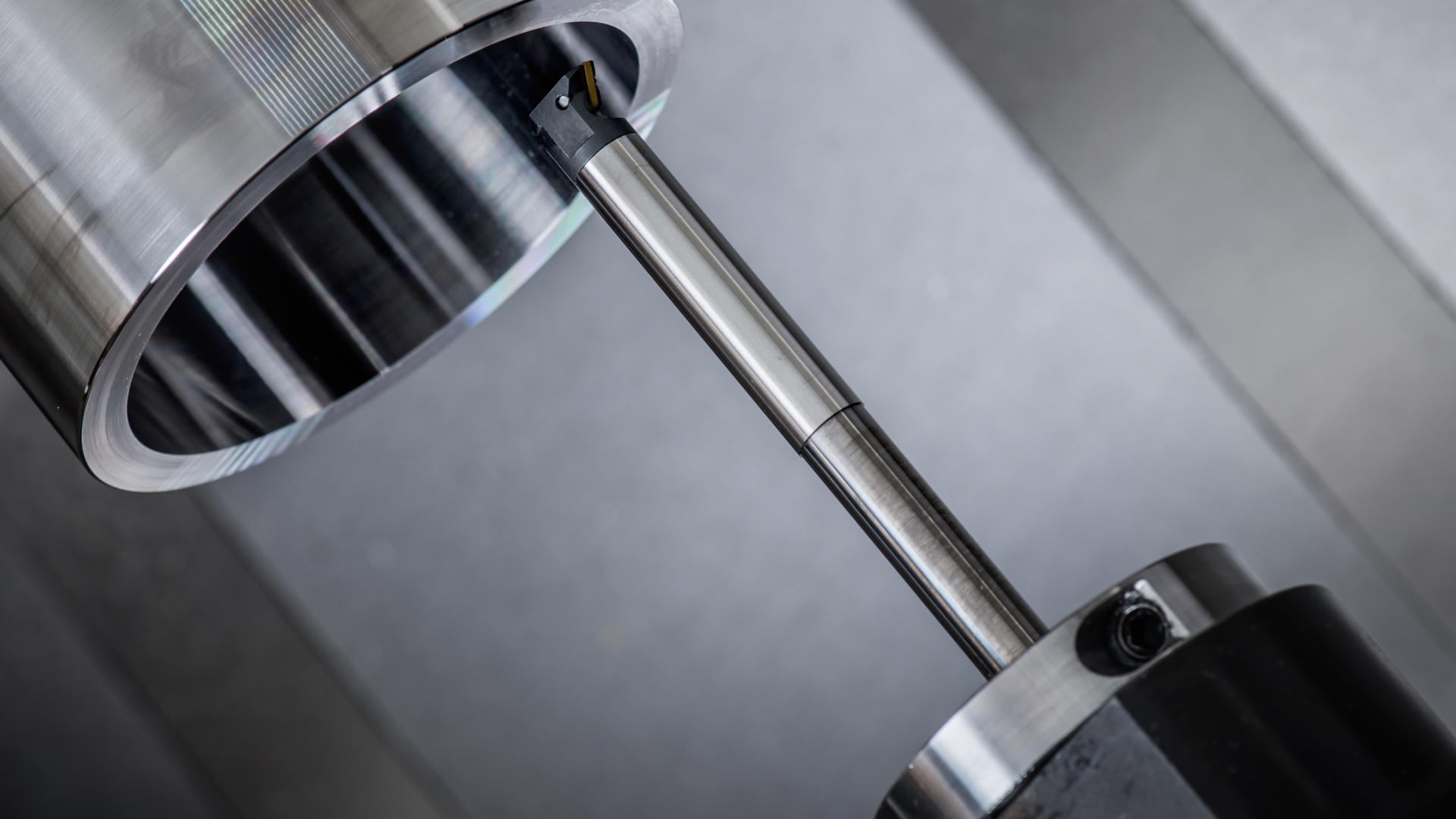

In metalworking, vibration is a persistent challenge that affects tool life, surface finish, and overall productivity. Traditional solutions like tunable mass dampers require frequent tuning to match the tool’s vibration frequency, making them inefficient and high-maintenance.

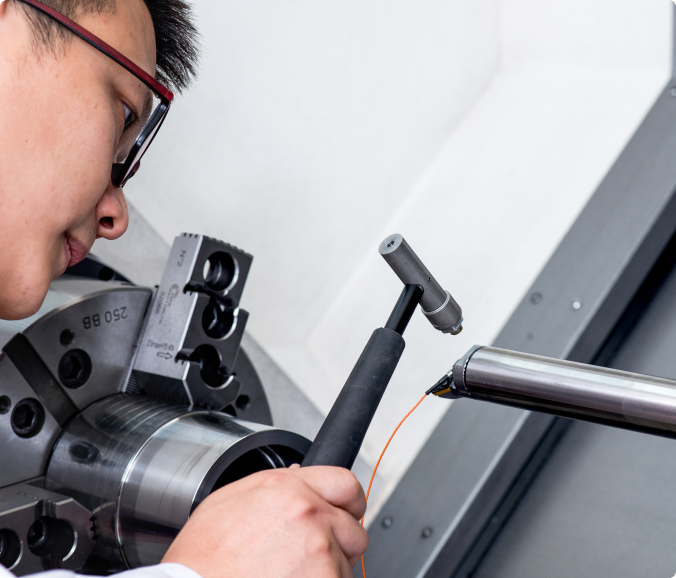

MAQ’s self-tuning mass damper (STMD™) technology offers an innovative, plug-and-play solution that automatically adapts to vibration changes, significantly enhancing machining performance without manual recalibration.

MAQ’s self-tuning mass damper (STMD™) technology addresses these limitations with automatic tuning that dynamically adapts to the tool’s vibration frequency. The ability to adapt dynamically to different setups makes STMD™ a game-changer for applications requiring varying tool lengths and conditions.

Experience the MAQ STMD™ in action, cutting at 500 m/min with an 11 L/D ratio.

Vibration, both stable and unstable, occurs naturally during cutting processes. Unstable vibration, or chatter, can cause tool breakage and surface defects, while stable vibration accelerates tool wear and leads to inconsistent surface quality. To eliminate these vibrations, damping technology is needed.

Mass dampers are a common solution; however, they must match their natural frequency to the tool’s exact vibration frequency. This presents challenges, as tool vibration frequencies vary depending on tool dimensions, material, and operating conditions. Traditional mass dampers often require manual tuning, leading to inefficiency, downtime, and increased operational costs.

• Frequency range: STMD™ covers a broad vibration frequency range, allowing it to handle tools with varying L/D (Length-to-Diameter) ratios effectively.

• L/D ratios covered: When other brands set a tight usable L/D ratio range (frequency range) on their tools to maintain its working sweet spot, the tools equipped with STMD can cover a wide L/D ratio range (frequency range) without compromising performance.

• Vibration Amplitude: STMD™ significantly reduces vibration amplitude when compared to traditional dampers. In tests, compared to the market’s dominant solutions using tuned mass dampers with viscous oil, conducted with turning tools at different L/D ratios:

The STMD tools further reduce the vibration amplitude by 20% in their sweet spot up to 50% outside their sweet spot.

• Plug & Play: STMD™ offers a plug-and-play experience. Once installed, the damper automatically adjusts to the tool’s vibration frequency without the need for manual tuning or recalibration. This maintenance-free solution ensures seamless integration into various machining setups, minimizing downtime and maximizing efficiency.

By eliminating the need for manual tuning, STMD™ enables substantial improvements in machining productivity:

Increased cutting speeds and feeds: With STMD™ technology, machines can operate at higher speeds and feeds without risking unstable vibrations.

Improved surface finish: STMD™ improves the quality of the machined surface by reducing vibration, allowing for more precise and smoother cuts.

Extended tool life: Vibration leads to accelerated tool wear. By damping vibrations, STMD™ extends the life of cutting tools by reducing wear rates.

The self-tuning mass damper (STMD™) technology is versatile and applicable across various industries:

• Aerospace: Achieve precision machining on lightweight, complex materials with minimal vibration.

• Automotive: Maintain consistent part quality in high-volume production, where tight tolerances are essential.

• General machining: Reduce rework, scrap, and downtime by controlling vibration during high-speed machining.

MAQ’s self-tuning mass damper (STMD™) technology provides a revolutionary solution to one of the biggest challenges in machining: controlling vibration. By automatically adjusting to vibration frequencies, STMD™ improves surface finish, increases tool life, and boosts overall productivity. For industries where precision and efficiency are critical – whether you’re a job shop owner or a manufacturing engineer – STMD™ offers a game-changing solution that reduces costs and maximizes performance.

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.