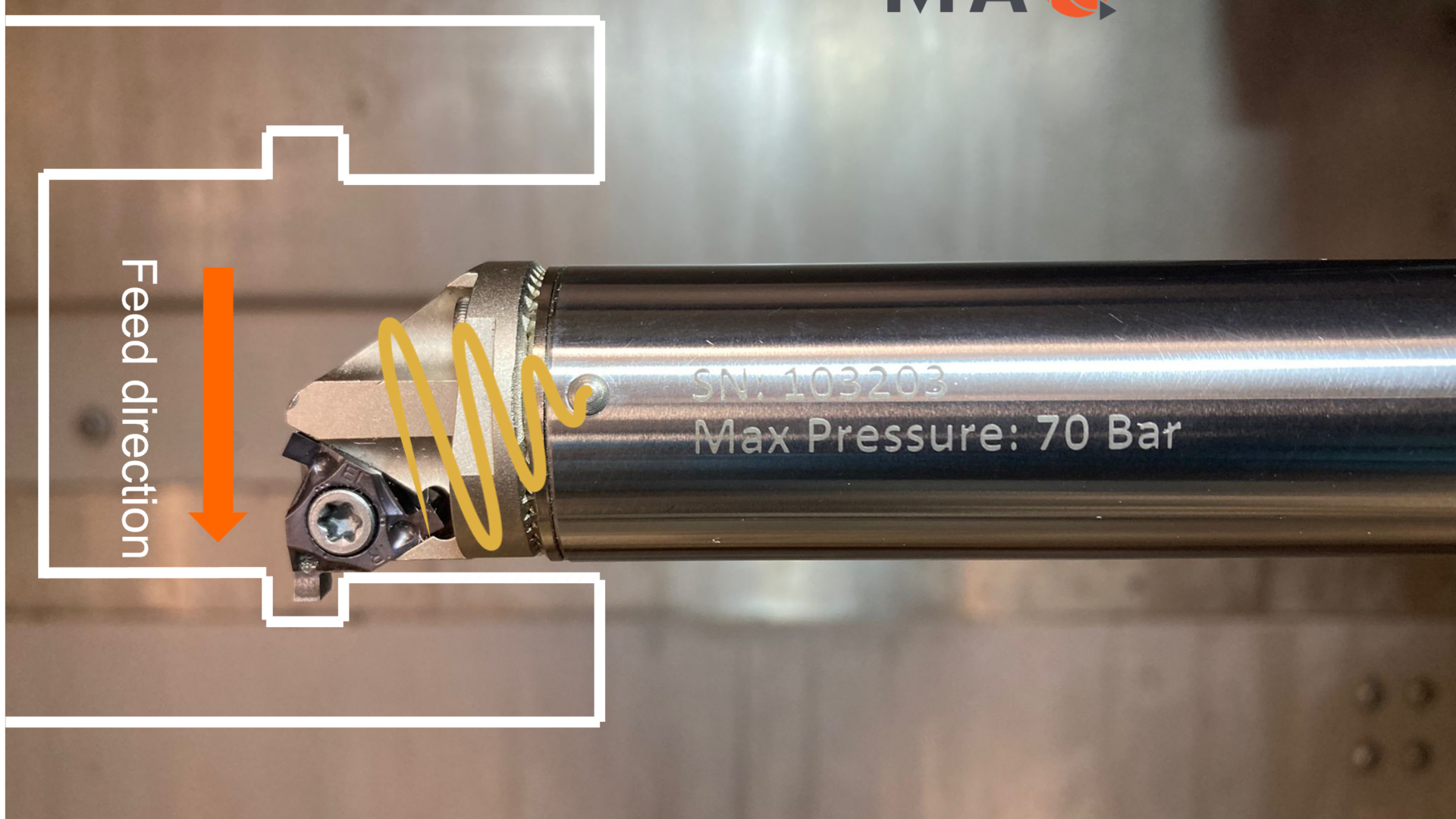

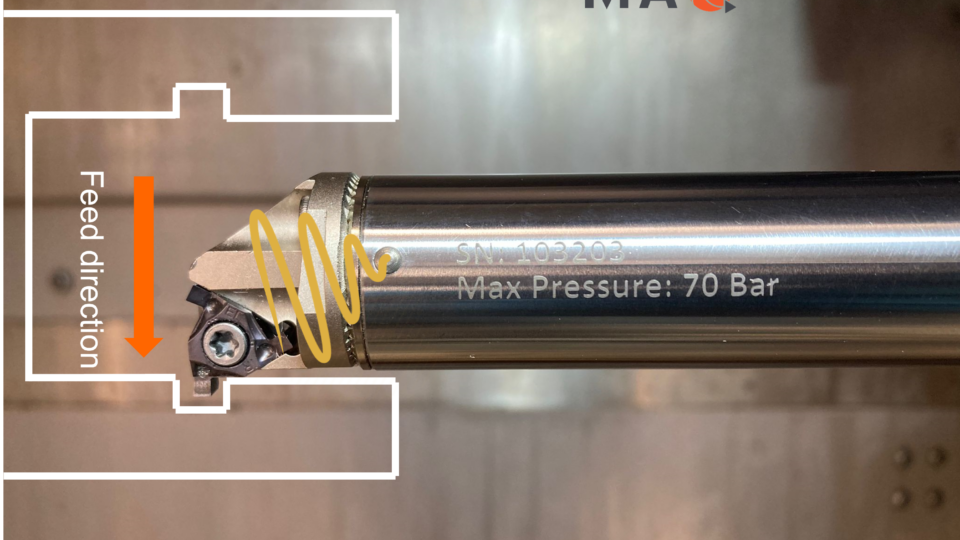

Internal grooving with threading style inserts on STMD tools at 8xD

Grooving has always been a challenging machining task, both for internal and external machining, due to its vibrations. Particularly for internal grooving operations, the feed force is aligned to the radial direction of the tool, and that excites substantial vibrations in the tool holder.

| Traditionally the recommendation is to use a steel damped bar for grooving operations above 5xD and a carbide-reinforced damped bar for operations 6-7xD. Above 7xD it has earlier been nearly impossible to do grooving. Thanks to MAQ, it’s now possible to do grooving operations up to 8xD!

Using an STMD M25-255 product which is a standard steel bar damped with the STMD technology, with an SXFNR 251724 16 cutter head and 16 IR W 2.25 insert, we perform grooving at 8xD overhang length. Machining in alloyed steel of 4340 HRC 28-30, the grooving process was smooth and quiet. Thanks to the STMD technology, with its Self-Tuning capabilities, the tool adapts to different types of vibrations, and the limits are again pushed by MAQ. See the video here. https://youtu.be/Kr4PPpImMxw Need to make a shallow groove for an O-ring seat or retaining rings? The standard selection of 16mm trigonal grooving inserts can help you make grooves with a max depth of 2.25mm. The width can be widened by a longitudinal turning operation. |

| Our mission is to bring new technology to the workshops to make things better, faster, and easier. “Simplify Machine” in other words!

Do not forget to visit our website; MAQ Web Site |