Contact-CTA or newsletter signup

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

Whitepaper

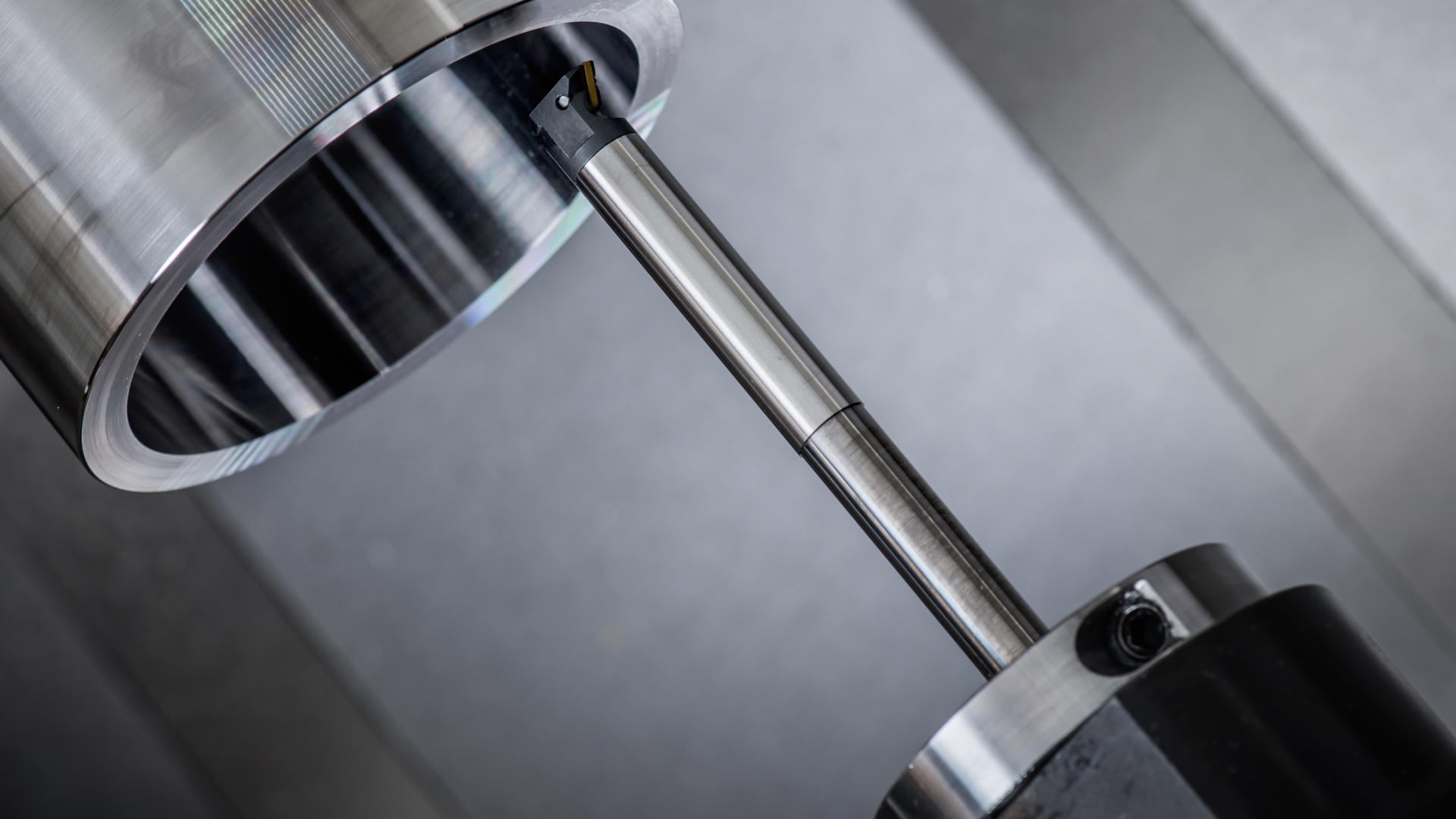

Vibration is one of the most challenging issues in metalworking. It not only compromises part quality but also leads to higher production costs due to damaged tools, poor surface finishes, and increased scrap rates. This is where advanced vibration damping in metalworking can make all the difference.

MAQ’s Self-Tuning Mass Damper (STMD™) technology addresses this problem by providing a cost-effective, advanced vibration damping solution. By integrating STMD™ into your operations, you can eliminate vibration issues in precision machining and significantly enhance machining productivity while improving tool life and cutting performance.

MAQ tools are a versatile choice for industries like aerospace, automotive, oil and gas, and medical component manufacturing, where precision is crucial. The technology is plug-and-play, requiring no maintenance or tuning, making it simple and easy to integrate into any production environment.

When you integrate MAQ STMD™ technology into your operations, you’re adopting a forward-thinking approach to vibration control. Our solutions are already delivering tangible results in industries like aerospace, automotive, oil and gas, and medical manufacturing, where vibration issues can compromise precision and quality.

MAQ’s vibration damped tools offer a unique value proposition as the only self-adjusting tool on the market, maximizing the mass damping effect without user intervention. By automating mass damping, MAQ allows you to focus on higher productivity, lower costs, and better results across every application.

MAQ’s STMD™ technology automatically adjusts to varying vibration frequencies, eliminating the need for frequent tuning. This self-adjusting innovation minimizes vibration and extends the life of both tools and machines, making it maintenance-free.

Industries like aerospace, automotive, and medical manufacturing benefit most, where vibration control is critical. MAQ’s vibration-damped tools are optimized for high length-to-diameter ratio (L/D) tools, significantly reducing vibration even in extreme cutting conditions.

The self-tuning technology works across a wide range of L/D ratios, reducing the need for multiple tools. For example, where competitors might need four different tools to cover L/D ratios from 5XD to 15XD, MAQ’s system only requires three, reducing tool cost investment and increasing productivity. MAQ offers a comprehensive range of tools to cover varying operations, including ISO back ends like HSK 100A, HSK 63A, PSC-C5, BT 40, and BT 50, and front ends like Arbor 6462.

The technology automatically adapts to changes in vibration frequencies, maintaining the highest energy transfer efficiency between the mass damper and the tool body, allowing manufacturers to boost productivity by 30-50% in the same machine setup.

With MAQ’s tools, manufacturers can realize higher feed rates and surface quality:

By eliminating the need for manual tuning, STMD™ enables substantial improvements in machining productivity:

Increased cutting speeds and feeds: With STMD™ technology, machines can operate at higher speeds and feeds without risking unstable vibrations.

Improved surface finish: STMD™ improves the quality of the machined surface by reducing vibration, allowing for more precise and smoother cuts.

Extended tool life: Vibration leads to accelerated tool wear. By damping vibrations, STMD™ extends the life of cutting tools by reducing wear rates.

• Aerospace: Achieve precision machining on lightweight, complex materials with minimal vibration.

• Automotive: Maintain consistent part quality in high-volume production, where tight tolerances are essential.

• General machining: Reduce rework, scrap, and downtime by controlling vibration during high-speed machining.

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.